Bio-inspired, compact and low-energy mass exchanger for carbon dioxide capture

Case ID: T002553

Web Published: 4/19/2024

Description:

Summary

Device composed of microchannels lined with sorbent-infused textured surfaces for CO2 capture and release via electrochemical regeneration

Institute Reference:

Background

There is growing consensus among the global scientific community that significant CO2 removal (up to 10 Gigatonnes/yr) will be needed to limit the Earth’s temperature rise to less than 1.5 ºC. Current estimates for the cost to capture a tonne of CO2 from the air vary widely, ranging from $100 to $1,000 per tonne. Capture of CO2 emissions of 10 gigatonnes per year would require about 10,000 large-scale Direct Air Capture plants. With each plant costing up to $500m, this would entail an investment of about $5 trillion. In addition, each facility would need to be stocked with solvent to absorb 10 gigatonnes of CO2 and be regenerated. Clearly, a new technology paradigm is needed to enable cost‑efficient carbon capture.

Technology Overview

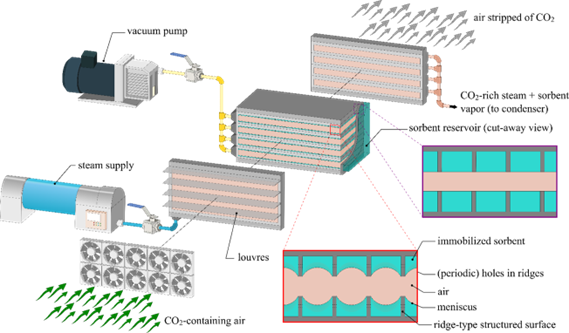

This CO2 capture approach is inspired by the pitcher plant which has a low-friction surface from a lubricant film trapped within the textures on the plant’s surface. Our design utilizes air (or flue gas) flow through micro/mini channels which are lined with sorbent-infused textured surfaces (SITS) that can capture CO2 from the flow stream.

Benefits

The enormous interfacial (gas-sorbent) area and mass transfer coefficient (per small hydraulic diameter) provided by micro or mini channels facilitates CO2 absorption. Importantly, the same device can be used for sorbent regeneration (electrochemical or thermal), wherein pure CO2 is released (for sequestration). Sorbent regeneration occurs in a periodic manner in the same device, wherein pure CO2 is released for sequestration. Electrochemical and/or thermal regeneration can be used. An additional benefit of the SITS is that they lubricate the streamwise flow of gas (per the menisci formed) relative to a no-slip (smooth) channel.

Applications

The mass exchanger concept has other applications including i) production of industrial gases, ii) alternative to existing processes involving gas-liquid mass exchange, iii) SOx, NOx, capture, iv) onsite O2 capture from air (a critical medical need) iv) high-performance heat exchangers and heat pipes.

Opportunity

We are interested in investment/ funding from interested parties to support both theoretical and experimental work to realize the technology. Work envisaged is (1) a detailed hybrid analytical-numerical approach to the study of CO2 (or other gas) mass transport along menisci of immobilized sorbents in textured surfaces, in order to predict the CO2 (or other gas) uptake rate, and (2) a holistic experimental approach to develop novel sorbents, which meet a multifunctional suite of properties related to CO2 selectivity, CO2 (or other gas) uptake capacity, gas diffusion, wettability, electrical conductivity and vapor pressure.

IP Status

- US provisional Patent Application 63/261,953 filed October 1, 2021; PCT Patent Application PCT/US22/77489 filed October 3, 2022

Keywords

analytical bio-inspired co2 capture co2 emissions co2 removal conductivity diffusion electrical electrical conductivity electrochemical emissions flue gas holistic hybrid industrial gas interfacial low-friction mass exchanger mass transfer menisci microchannel microchannels multifunctional nox regeneration scale selectivity sequestration solvent sorbent-infused textured surface transport vapor vapor pressure

Seeking

Suggested Companies

O&G players using CO2 for Enhanced Oil Recovery

Carbon capture players such as Climeworks, Carbon Engineering, Remora…

Patent Information:

- App Type

- Country

- Serial No.

- Patent No.

- File Date

- Issued Date

- Expire Date

Direct Link: http://tufts.technologypublisher.com/technology/53979

Category(s):

Share

Inventors:

Keywords: